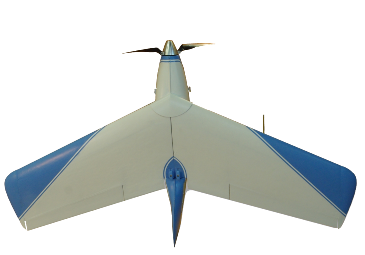

Flying Wing Prototype

Flying Wing Prototype

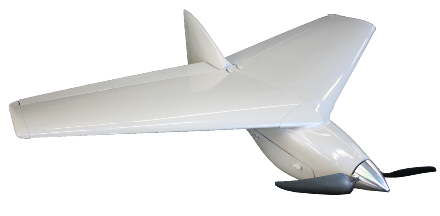

The vehicles produced utilizing Brandebury Tool Company’s proprietary manufacturing processes have an extremely light & robust airframe. Examples include an autopilot test vehicle built for use as a high performance hand launched UAV.

Lightweight to the Core

Fuselages are constructed from high density EPP foam and wrapped in a lightweight but high strength polycarbonate skin. The monocoque structure of the skin design creates an airframe capable of withstanding high impacts.

Durable Outer Skin

The wings are CNC wire cut from EPP foam and covered with a two part reinforced skin. The wing core is wrapped with a fiberglass skrim and covered with a PET Film that can be screen printed or painted on the inside surface.

Quick Assembly

We can provide captive fasteners and our proprietary wing attachment methods (patent pending) along with mechanical or electrical servo connections for quick field assembly.

Integrated Electronics

Built in components and raceways accommodate your flight controller, antenna arrays and other sensors. Compartments are a part of the airframe’s unique monocoque design

Integrated Electronics

Rapid Prototyping

Our in house tooling process goes directly from the CAD design to machine coding and fabrication. This allows for very quick tooling of thermoplastic skin requirements and compartmentalized EPP cores.

Weight & Size

| Wingspan | 38.8" |

|---|---|

| Airframe Weight | 22 oz |

| RC Flying Weight | 44 oz |

Power

| Power | Brushless Outrunner |

|---|---|

| Max Speed | 70 kts |

| Stall Speed | 18 kts |