TigerShark

TigerShark

The TigerShark airframe is built using plywood laminate components and incorporates lightening holes, slot sockets and tabs. The RTF airframe includes 17 ft composite wings, weighs less than 160 lbs and has an available payload capacity of over 150 lbs.

FoxCar

The Foxcar airframe is a TigerShark fuselage with a larger 21 foot composite wing and canted composite tail fins. This configuration weighs less than 175 lbs, and allows for a lighter wing loading and extended duration flight as well as larger payloads.

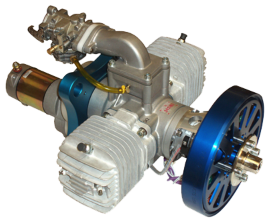

Power Plant

A 3W 340cc 30hp opposed twin engine is one of several optional powerplants for the TigerShark.

Quick Field Assembly

This twin boom pusher can easily be assembled or disassembled in the field. The boom attachment system is connected via two bolts and a strut brace to the landing gear.

Production Engineering

The TigerShark has been developed with easy to assemble interchangeable CNC parts assuring strict quality control and accurate parts alignment.

On Board Pneumatics

The TigerShark features Brandebury Tool Company’s AeroPneumatic braking system. (patent pending) This fully differential and proportional braking systems features a stand alone compressor, weight less than 12 oz.

Weight & Size

| Wingspan | 17' (FoxCar 21') |

|---|---|

| Length | 15'6" (FoxCar 16') |

| Empty Weight | 150 lbs (FoxCar 170 lbs) |

| Gross Takeoff Weight | 350 lbs |

Power

| Endurance | 12 Hrs |

|---|---|

| Power Plant | 3W 340cc |

| Power | 30 HP |

| Payload Capacity | >150 lbs |

| Max Speed | 110 kts |

| Stall Speed | 40 kts |